Package Include

Bobcat Direct Drive Auger Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-74

Publication Number

6900889enUS (February-2018)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 3 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bobcat Auger Models of :

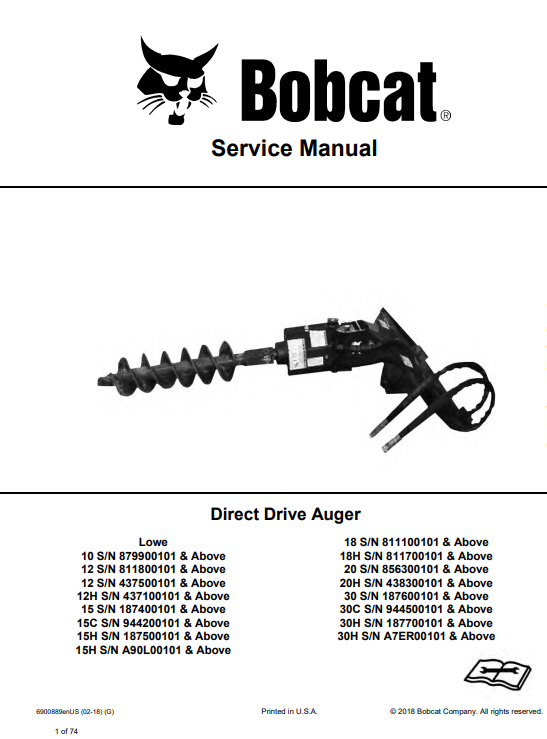

Compatible Model : Bobcat Direct Drive Auger

Compatible Serial Numbers :

10 S/N 879900101 & Above

12 S/N 811800101 & Above

12 S/N 437500101 & Above

12H S/N 437100101 & Above

15 S/N 187400101 & Above

15C S/N 944200101 & Above

15H S/N 187500101 & Above

15H S/N A90L00101 & Above

18 S/N 811100101 & Above

18H S/N 811700101 & Above

20 S/N 856300101 & Above

20H S/N 438300101 & Above

30 S/N 187600101 & Above

30C S/N 944500101 & Above

30H S/N 187700101 & Above

30H S/N A7ER00101 & Above

Contents of this pdf service manual

SAFETY & MAINTENANCE

HYDRAULIC SYSTEM

MAINFRAME

Understanding the Bobcat Direct Drive Auger System

The Bobcat Direct Drive Auger system represents a significant advancement in augering technology, offering enhanced efficiency and versatility in various applications. This system is designed to operate seamlessly with Bobcat machinery, featuring a robust design that minimizes wear and tear while providing maximum performance. A crucial component of this system is the hydraulic motor, which delivers reliable torque directly to the auger bit, making it far more efficient than conventional chain-driven augers.

In terms of technical specifications, the Bobcat Direct Drive Auger typically comes in various sizes and configurations, allowing it to tackle diverse tasks such as digging holes for fence posts, planting trees, or installing signposts. The direct drive mechanism translates hydraulic power into rotational force without the need for cumbersome belts or chains, resulting in improved reliability and lower maintenance requirements. This design also enhances the operator’s control, enabling precise drilling and reducing the risk of damaging the surrounding landscape.

The advantages of utilizing a direct drive auger system are manifold. Compared to traditional auger setups, which often incur energy losses during power transmission, the direct drive configuration optimizes energy efficiency. Another significant benefit is the reduced risk of equipment failure, as fewer moving parts lead to diminished wear and downtime. However, despite its robust design, operators may encounter common issues, such as overheating or inadequate torque application. Understanding these potential challenges is vital for any user looking to maintain their Bobcat Direct Drive Auger effectively.

Overall, the Bobcat Direct Drive Auger system stands out for its operational efficiency and reliability, making it a valuable tool for contractors, landscapers, and DIY enthusiasts alike, significantly improving the overall productivity of drilling operations.

Step-by-Step Repair and Maintenance Procedures

Performing repairs and maintenance on the Bobcat Direct Drive Auger is essential to ensure its optimal functionality and longevity. To begin, gather the necessary tools, which typically include wrenches, screwdrivers, pliers, a filter wrench, and a torque wrench. Having a comprehensive toolkit will enable you to tackle various repair and maintenance tasks effectively.

Routine maintenance tasks should be carried out regularly to prevent breakdowns and costly repairs. One key routine task is to inspect and clean the auger bits to ensure they remain sharp and free from debris. It is also vital to check hydraulic fluid levels and replace filters according to the manufacturer’s schedule. Periodically greasing joints and bearings will help reduce friction and wear, thereby extending the equipment’s lifespan.

When diagnosing common problems, the first step is to observe signs of wear or damage, such as unusual noises or decreased performance. If the auger’s power seems to drop, check the hydraulic system for any leaks or blockages. Additionally, there may be electrical issues to consider, so inspecting wiring and connections for signs of corrosion or disconnection is advisable.

Health and safety precautions are paramount when working on machinery. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots. Ensure that the auger is powered off and securely positioned before starting any service work. Familiarize yourself with the equipment’s safety manual, as it provides critical information to prevent accidents and injuries.

When sourcing replacement parts, it is recommended to use OEM parts whenever possible to maintain the integrity and performance of the auger. Contact your local Bobcat dealer or consult the official website for a reliable supply of parts. Following these step-by-step procedures will empower Bobcat owners and operators to maintain their Direct Drive Auger effectively. By doing so, they can enjoy increased efficiency and a longer service life from their equipment.