Package Include

Bobcat HB Series Hydraulic Breaker Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-138

Publication Number

6904105enUS (July 2016)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 5 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bobcat Hydraulic Breaker Models of :

Compatible Models and Serial Numbers :

Bobcat Breaker HB280 [S/N A5T500101 & Above]

Bobcat Breaker HB380 [S/N A01Q00101 & Above (Europe Only)]

Bobcat Breaker HB580 [S/N A00V00101 & Above (Europe Only)]

Bobcat Breaker HB680 [S/N A00W00101 & Above]

Bobcat Breaker HB880 [S/N A00X00101 & Above]

Bobcat Breaker HB980 [S/N A00Y00101 & Above]

Bobcat Breaker HB1180 [S/N A01R00101 & Above]

Contents of this pdf service manual

BOBCAT BREAKER HB1180) HYDRAULIC BREAKER SPECIFICATIONS

BOBCAT BREAKER HB280) HYDRAULIC BREAKER SPECIFICATIONS

BOBCAT BREAKER HB380) HYDRAULIC BREAKER SPECIFICATIONS

BOBCAT BREAKER HB580) HYDRAULIC BREAKER SPECIFICATIONS

BOBCAT BREAKER HB680) HYDRAULIC BREAKER SPECIFICATIONS

BOBCAT BREAKER HB880) HYDRAULIC BREAKER SPECIFICATIONS

BOBCAT BREAKER HB980) HYDRAULIC BREAKER SPECIFICATIONS

ATTACHMENT IDENTIFICATION

ATTACHMENT STORAGE AND RETURN TO

SERVICE

BREAKER HOUSING

BREAKER

DAILY INSPECTION

DELIVERY REPORT

DIVERTER VALVE (S/N A00X05151 & BELOW, S/N A00Y06088 & BELOW)

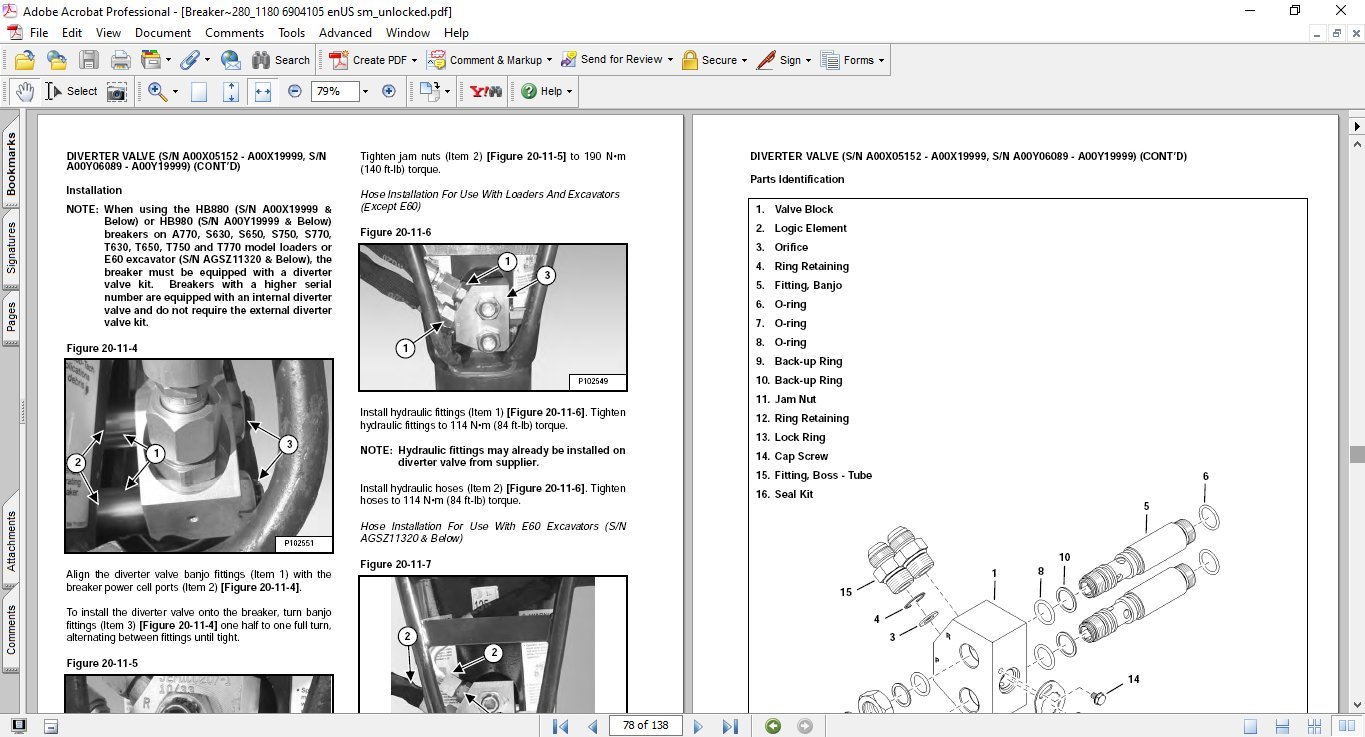

DIVERTER VALVE (S/N A00X05152 – A00X19999, S/N A00Y06089 – A00Y19999)

HYDRAULIC CONNECTION SPECIFICATIONS

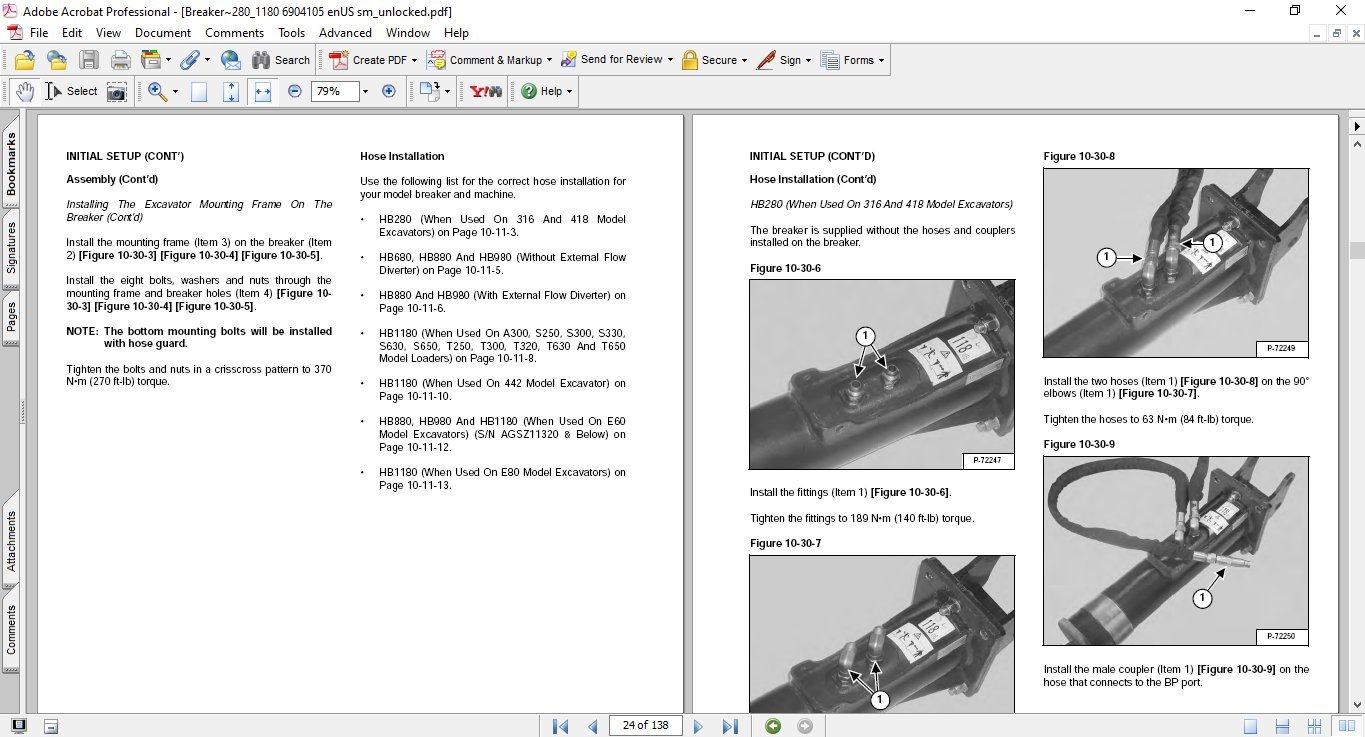

INITIAL SETUP

LUBRICATING THE ATTACHMENT

MAINTENANCE SAFETY

REGULAR MAINTENANCE ITEMS

REMOVAL AND INSTALLATION OF TOOL

SCHEMATICS

SERIAL NUMBER LOCATION

SERVICE SCHEDULE

TORQUE SPECIFICATIONS FOR BOLTS

TROUBLESHOOTING

Introduction to Bobcat HB Series Hydraulic Breakers

The Bobcat HB Series Hydraulic Breakers are specialized attachments designed to enhance the versatility of Bobcat excavators and loaders in various applications. Renowned for their robust construction and innovative technology, these breakers are an essential tool in the arsenal of construction and demolition professionals. They are uniquely engineered to efficiently break through concrete, rock, and other tough materials, making them indispensable for tasks such as foundation work, road repairs, and heavy demolition.

One of the distinguishing features of the HB Series is the optimized hydraulic system that provides maximized impact energy with minimal vibration to the host machine. This results in greater efficiency and productivity on job sites, allowing operators to complete tasks more quickly and effectively. Additionally, Bobcat Hydraulic Breakers are designed with an integrated suspension system that absorbs shock, enhancing both performance and durability. Users can expect reliable operation, even in the most challenging conditions.

Proper maintenance of the Bobcat HB Series is crucial for ensuring longevity and peak performance. Regular inspection and upkeep not only prevent premature wear and tear but also help in addressing potential issues before they escalate into significant problems. Common challenges users may encounter include the wear of chisels, hydraulic leaks, and performance inconsistencies. Consequently, possessing a comprehensive service repair manual is vital. This manual provides users with detailed maintenance procedures, troubleshooting guides, and other critical information, empowering operators to address common issues effectively and maintain their equipment in optimal condition.

In summary, the Bobcat HB Series Hydraulic Breakers stand out for their durability, efficiency, and adaptability in various tasks. Understanding their features and the importance of maintenance can significantly impact operational success and equipment lifespan.

Service and Repair Guidelines

Servicing and repairing the Bobcat HB Series Hydraulic Breakers requires a systematic approach to maintain their efficiency and longevity. Regular maintenance is crucial, as it not only prevents major breakdowns but also enhances the overall performance of the hydraulic breaker. Operators should begin by conducting routine checks on the hydraulic systems, ensuring that fluid levels are within the recommended range and that there are no leaks in the connections. Consistent monitoring can help detect early signs of wear that may demand attention.

In addition to regular inspections, operators should consider implementing a schedule for more comprehensive maintenance operations, such as replacing wear parts. Components like chisels and bushings come under significant stress during operation and should be replaced according to the specific maintenance intervals outlined in the service manual. Correctly identifying the wear indicators on these parts will help ensure the hydraulic breaker operates effectively and safely.

When troubleshooting the Bobcat HB Series, attention should be given to unusual symptoms such as excessive vibration, reduced power, or hydraulic fluid leaks. These signs often suggest underlying issues, which may include hydraulic system malfunctions or problems with specific components. Having the right tools for diagnosing and repairing these issues is essential; a comprehensive toolset tailored for hydraulic breaker repairs can streamline the process and minimize downtime.

Safety measures cannot be overstated in the servicing and repair of hydraulic breakers. Operators and maintenance personnel must adhere to stringent safety protocols, including wearing appropriate personal protective equipment (PPE) and following lockout/tagout procedures during maintenance tasks. By maintaining an organized workspace and utilizing the correct tools and precautions, the risk of accidents and injuries can be significantly reduced.

In summary, operators of the Bobcat HB Series Hydraulic Breakers must engage in diligent service and repair practices to maximize equipment performance and safety. By performing routine inspections, addressing wear parts proactively, and following stringent safety measures, they can ensure the hydraulic breakers remain in optimal working condition. This comprehensive approach to maintenance will ultimately extend the lifespan of the hydraulic equipment and promote reliable operation on job sites.