Package Include

Bobcat Hydraulic Breaker B700, B850, B950, B1400 Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-200

Publication Number

6901152 ( (June 2012)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 9 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bobcat Hydraulic Breaker Models of :

Compatible Models :

Bobcat Hydraulic Breaker B700

Bobcat Hydraulic Breaker B850

Bobcat Hydraulic Breaker B950

Bobcat Hydraulic Breaker B1400

Compatible Serial Numbers :

S/N 733200101 & Above

S/N 794000101 & Above

S/N 797000101 & Above

S/N 797100101 & Above

Contents of this pdf service manual

ACCUMULATOR DISASSEMBLY AND ASSEMBLY

BREAKER BIT ASSEMBLY

BREAKER FRAME

BREAKER LUBRICATION

BUSHING REMOVAL AND INSTALLATION

ENERGY/FREQUENCY PISTON (B700)

HOSE INSTALLATION

HYDRAULIC FLUID FLOW EXPLANATION (B700)

NITROGEN CHAMBER

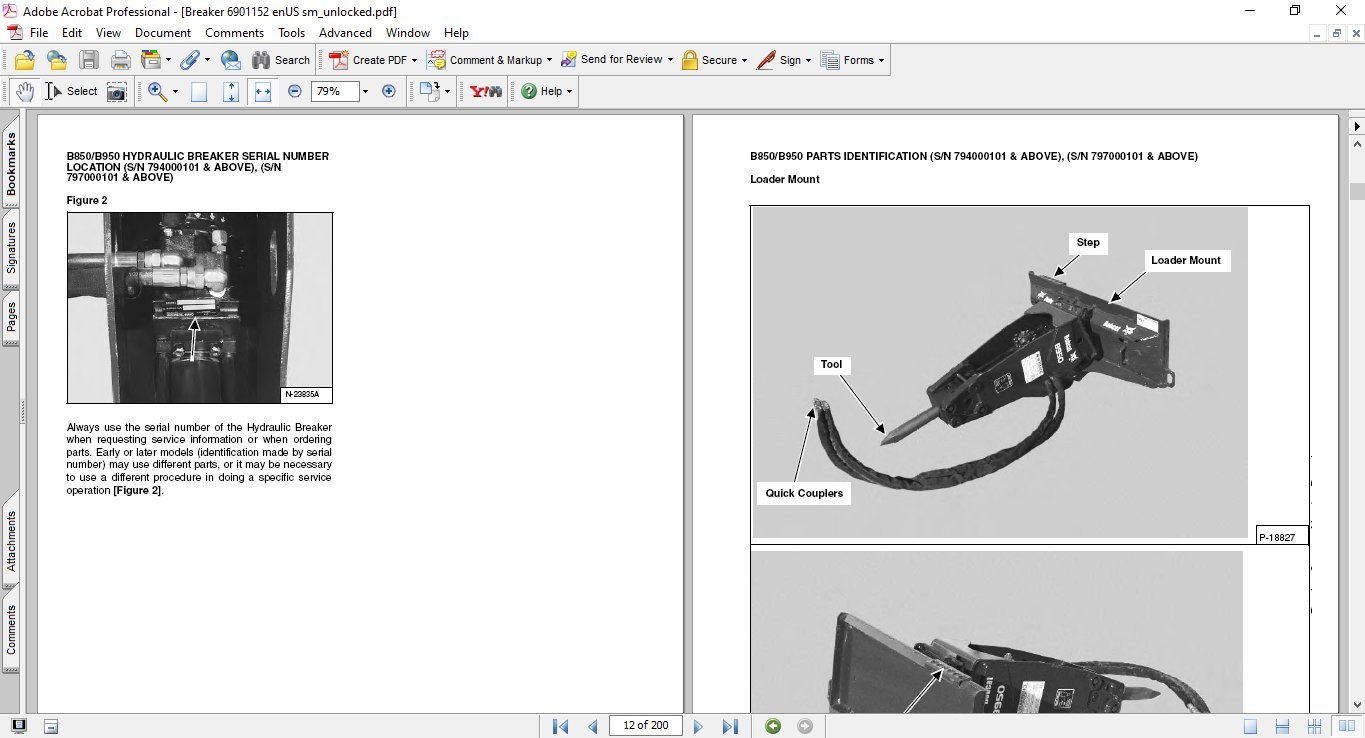

PARTS IDENTIFICATION

SERIAL NUMBER LOCATION.

SPECIFICATIONS AND SCHEMATICS

Overview of Bobcat Hydraulic Breakers B700, B850, B950, B1400

Bobcat hydraulic breakers are renowned for their efficiency and durability, making them essential tools in the construction and demolition industries. Among the popular models are the B700, B850, B950, and B1400, each designed to meet specific operational demands while ensuring maximum performance. These hydraulic breakers are engineered with advanced technology, providing operators with reliable solutions for various heavy-duty tasks.

The B700 model is typically recommended for smaller machines and is ideal for light to medium demolition tasks. It features a compact design that enhances maneuverability in tight spaces, making it suitable for urban construction sites. In contrast, the B850 model is designed for medium-sized machines and offers increased power and impact force, making it versatile for a variety of applications, including breaking concrete and asphalt.

The B950 model raises the bar with enhanced capabilities, especially for larger machinery. It is characterized by superior energy efficiency and reliability, making it a preferred choice for significant infrastructure projects. Furthermore, the B1400 stands as the most powerful option among the four. This hydraulic breaker is specifically tailored for heavy-duty applications, providing unmatched performance in the demolition of large structures and tough materials.

Each hydraulic breaker is equipped with features that enhance their operational efficiency, such as anti-blank firing systems and automatic lubrication capabilities, which result in lower maintenance needs and longer service life. The importance of possessing a comprehensive service and repair manual cannot be overstated; it allows operators to perform regular maintenance, troubleshoot issues effectively, and ensure optimal performance throughout the lifetime of the equipment. This meticulous approach not only extends the life of the equipment but also reinforces operational safety and efficiency.

Service and Repair Procedures for Bobcat Hydraulic Breakers

Maintaining the optimal performance of Bobcat Hydraulic Breakers, including models B700, B850, B950, and B1400, requires adherence to specific service and repair procedures. Regular maintenance is essential to prevent breakdowns and prolong the equipment’s operational lifespan. The primary focus should be on routine checks, troubleshooting, and executing repairs when necessary.

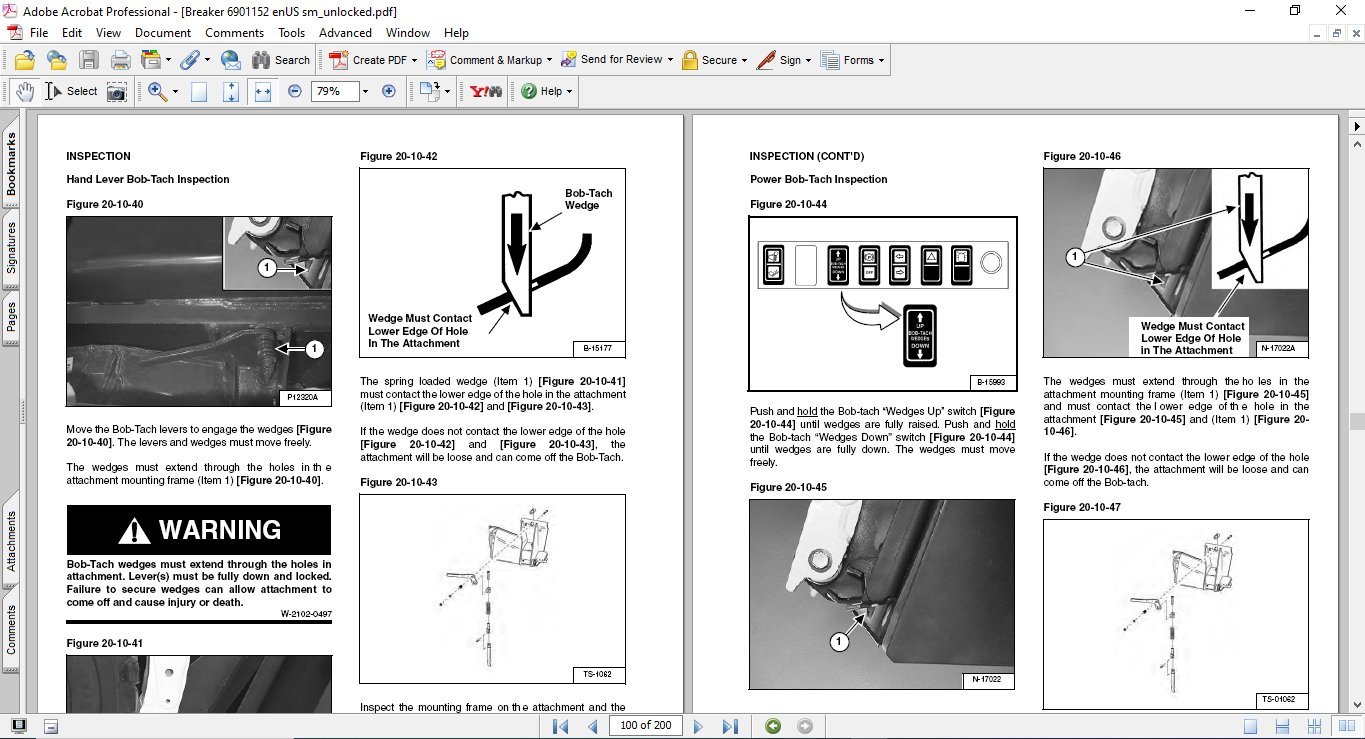

To begin with, it is imperative to conduct routine maintenance checks. This includes inspecting the hydraulic system for any leaks, ensuring proper fluid levels, and testing the operation of the breaker. Additionally, inspect the chisel or bit for any signs of wear or damage. If the bit has worn down or become chipped, it should be replaced to maintain efficiency. Cleaning the breaker thoroughly to remove dirt and debris is also crucial to avoid unnecessary wear.

In troubleshooting common issues, operators should be aware of symptoms such as reduced performance or unusual noises during operation. If the breaker fails to operate correctly, users should first check the hydraulic pressure and confirm that the correct pressure settings are maintained as per the manufacturer’s guidelines. Additionally, it is essential to inspect hoses and connections for signs of wear or obstructions that may hinder performance.

For more serious repairs, having the right tools on hand is critical. Typical tools required may include wrenches, screwdrivers, hydraulic fluid, and replacement components like seals or O-rings. When performing repairs, always ensure that the equipment is turned off and depressurized to minimize any risk of accidents. Following the manufacturer’s recommended practices during these procedures not only assures safety but also guarantees efficient repair.

By equipping oneself with a comprehensive understanding of service and repair procedures, operators can ensure their Bobcat hydraulic breakers function optimally, minimizing downtime and enhancing performance throughout their operational lifetime.