Package Include

Bobcat Hydraulic Breaker HB1380, HB2380 Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-108

Publication Number

6904929 (March 2009)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 3 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bobcat Hydraulic Breaker Models of :

Compatible Models and Serial Numbers :

Bobcat Breaker HB1380 S/N AC4500101 & Above

Bobcat Breaker HB2380 S/N A5T600101 & Above

Contents of this pdf service manual

ATTACHMENT DELIVERY REPORT

BREAKER

BREAKER HOUSING

BREAKER LUBRICATION

HOSE INSTALLATION

IDENTIFICATION AND MACHINE SIGN (DECALS)

INSPECTION

MOUNTING FRAME INSTALLATION

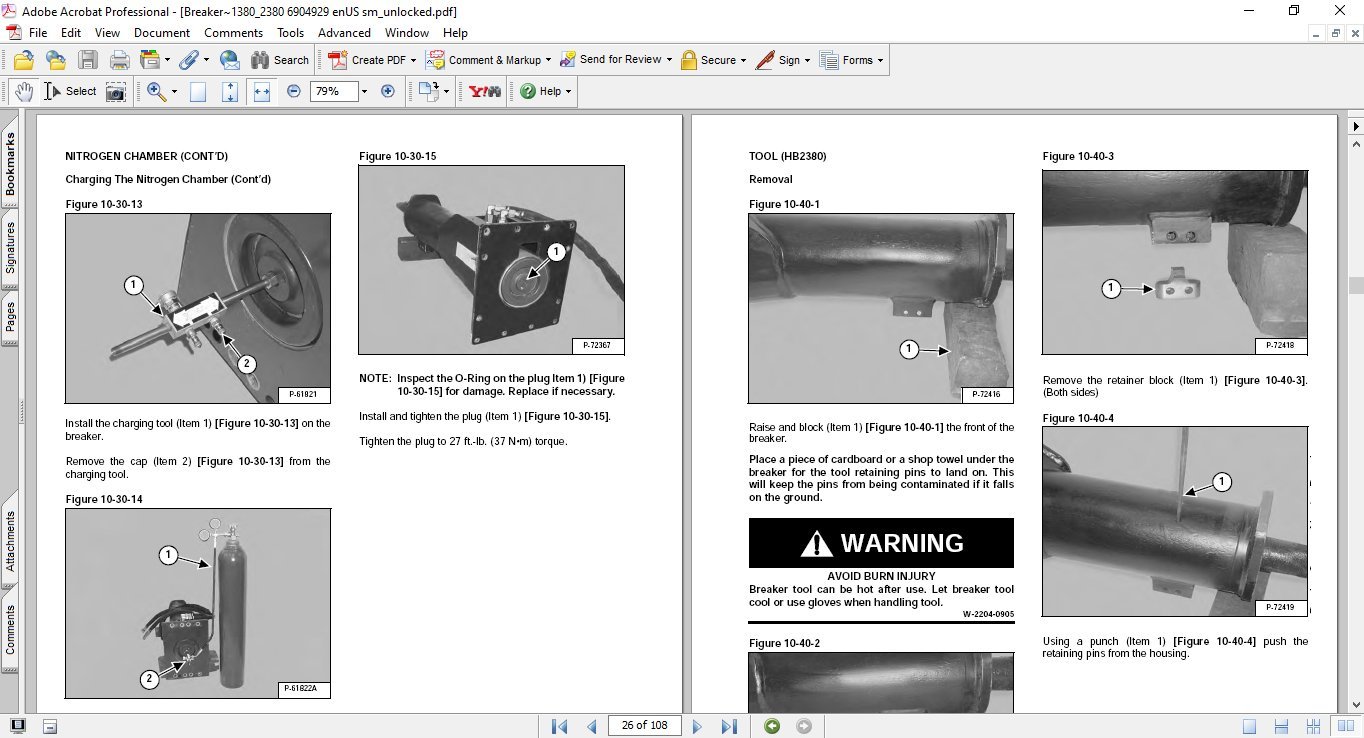

NITROGEN CHAMBER

SERIAL NUMBER LOCATIONS

SPECIFICATIONS (HB2380)

STORAGE PROCEDURES

TOOL

TROUBLESHOOTING

Overview of Bobcat Hydraulic Breakers HB1380 and HB2380

The Bobcat Hydraulic Breakers HB1380 and HB2380 are integral tools designed for various construction and demolition applications. Both models demonstrate a commitment to efficiency and power, making them suitable for heavy-duty tasks. The HB1380 model weighs approximately 1,380 pounds and boasts an impressive power-to-weight ratio, optimized for medium to heavy-duty applications. In contrast, the HB2380 model, at around 2,380 pounds, delivers enhanced performance capabilities, catering to more demanding conditions such as large-scale demolition or rock breaking projects.

One of the primary distinguishing features of both models is their operating weight, leading to different applications. The HB1380 excels in urban environments where versatility is essential, allowing for effective operation in confined spaces. Conversely, the HB2380 is engineered for more intense workloads, providing users with the robustness required for extensive demolition sites and tougher materials.

Specifications for both hydraulic breakers highlight their similar design intent. Each unit incorporates advanced technology for reduced vibration and improved efficiency, resulting in less operator fatigue and increased productivity. A noteworthy innovation in these models is the inclusion of a patented accumulator, which maximizes energy transfer during operation, enhancing overall performance and effectiveness.

The applications of Bobcat Hydraulic Breakers extend across multiple sectors, including construction, infrastructure development, and landscaping. They are particularly effective for breaking concrete, asphalt, and rock, making them invaluable in both demolition and site preparation tasks. Utilizing hydraulic breakers not only streamlines the process of material removal but also minimizes the physical strain on operators, contributing to safer working conditions.

In summary, the Bobcat Hydraulic Breakers HB1380 and HB2380 are engineered for reliability in a range of applications, each offering unique advantages tailored to different operational needs. These models represent a significant advancement in the construction equipment sector, providing powerful solutions for modern industry challenges.

Service and Repair Manual for HB1380 and HB2380

The Bobcat Hydraulic Breakers HB1380 and HB2380 are essential tools for many construction and demolition projects. To ensure their longevity and efficient operation, adhering to a well-structured service and repair manual is crucial. Regular maintenance not only enhances performance but also minimizes downtime. Key maintenance practices include regular inspections, lubrication, and cleaning of the hydraulic system, as these steps help avert potential issues.

Common issues that may arise with the HB1380 and HB2380 models include leaks, reduced breaking force, and abnormal noise during operation. Troubleshooting these problems often starts with a thorough inspection of the hydraulic lines and seals. If a leak is detected, it is essential to assess the integrity of the seals and hoses, replacing any damaged components promptly. For reduced breaking force, operators are advised to check for air in the hydraulic lines and to ensure that the hydraulic fluid is at the recommended level. Abnormal sounds could indicate internal wear, necessitating closer examination of the piston and electrical connections.

When undertaking repairs, it is recommended to follow the step-by-step procedures detailed in the service manual closely. This usually involves isolating the breaker from power sources, properly securing it, and using the appropriate tools. Essential tools may include wrenches, screwdrivers, and a hydraulic pump. Operators must also prioritize safety, wearing protective gear and following lockout/tagout procedures before commencing work on the breakers. Additionally, efficient maintenance practices such as scheduled inspections and timely repairs can significantly prevent extensive damage and costly repairs in the future.

Ultimately, by adhering to the outlined service and repair manual for the Bobcat Hydraulic Breakers HB1380 and HB2380, operators can ensure optimal functionality and extend the lifespan of their hydraulic equipment.