Package Include

Bobcat Hydraulic Breaker Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-260

Publication Number

6720280 ( (June 2012)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 7 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bobcat Hydraulic Breaker Models of :

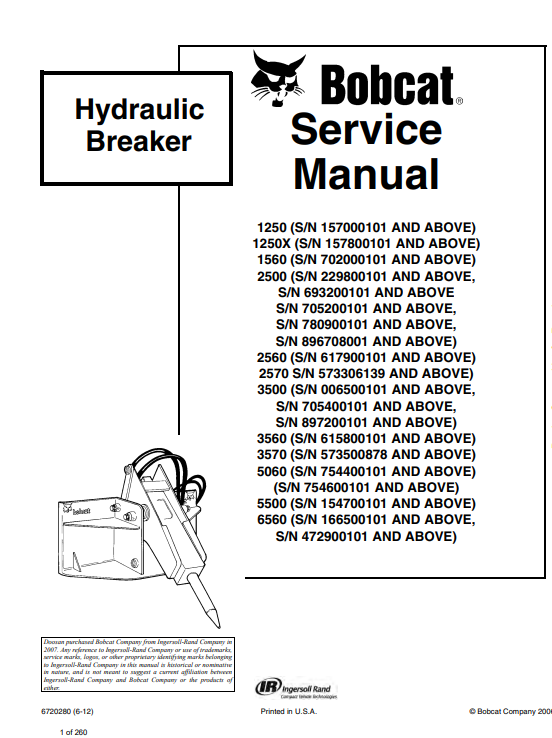

Compatible Model and Serial Numbers :

Bobcat1250 (S/N 157000101 AND ABOVE)

Bobcat1250X (S/N 157800101 AND ABOVE)

Bobcat1560 (S/N 702000101 AND ABOVE)

Bobcat2500 (S/N 229800101 AND ABOVE, S/N 693200101 AND ABOVE, S/N 705200101 AND ABOVE, S/N 780900101 AND ABOVE, S/N 896708001 AND ABOVE)

Bobcat 2560 (S/N 617900101 AND ABOVE)

Bobcat 2570 S/N 573306139 AND ABOVE)

Bobcat 3500 (S/N 006500101 AND ABOVE , S/N 705400101 AND ABOVE, S/N 897200101 AND ABOVE)

Bobcat3560 (S/N 615800101 AND ABOVE)

Bobcat 3570 (S/N 573500878 AND ABOVE)

Bobcat 5060 (S/N 754400101 AND ABOVE) (S/N 754600101 AND ABOVE)

Bobcat 5500 (S/N 154700101 AND ABOVE)

Bobcat 6560 (S/N 166500101 AND ABOVE , S/N 472900101 AND ABOVE)

Contents of this pdf service manual

1250X HYDRAULIC BREAKER SERVICE

ACCUMULATOR

ASSEMBLY

DISASSEMBLY

PARTS IDENTIFICATION

SPECIFICATIONS

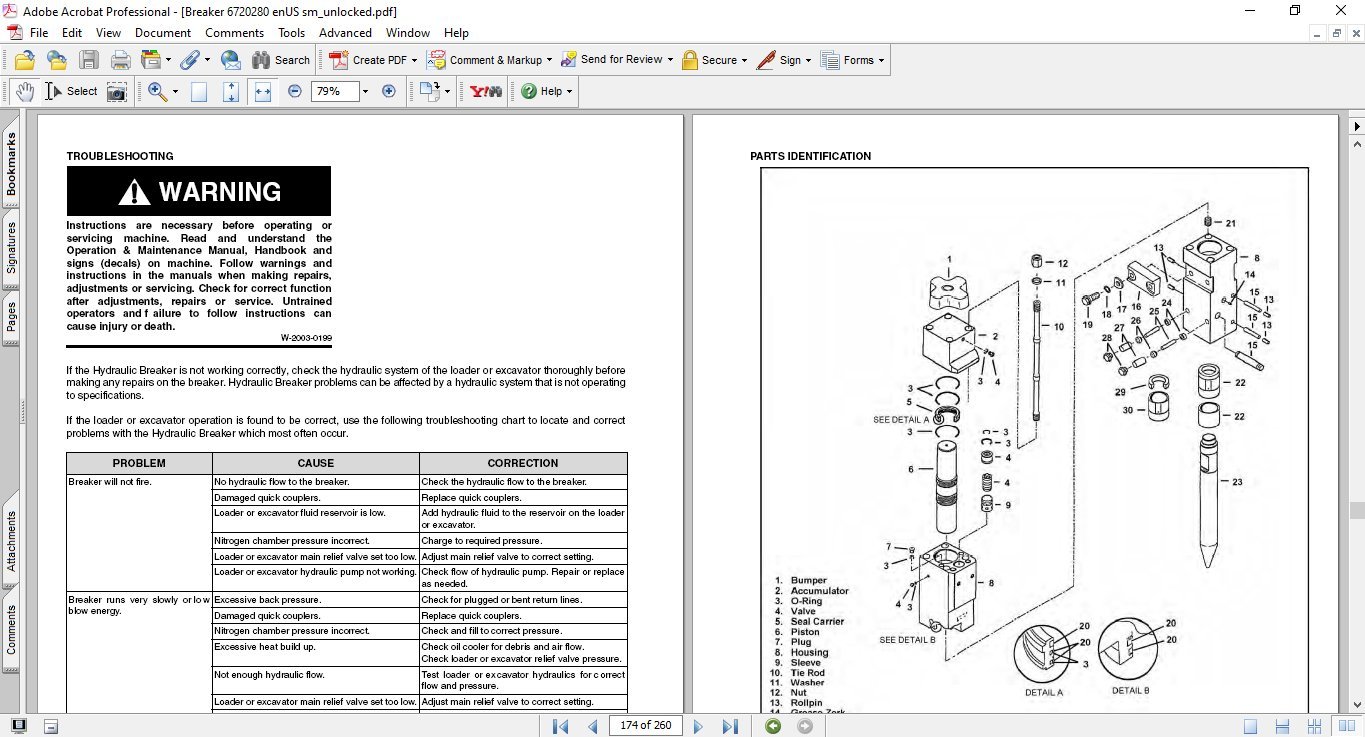

TROUBLESHOOTING THE HYDRAULIC BREAKER

1560 HYDRAULIC BREAKER SERVICE

CHECKING MOUNTING BOLT TORQUE

HYDRAULIC BREAKER LUBRICATION

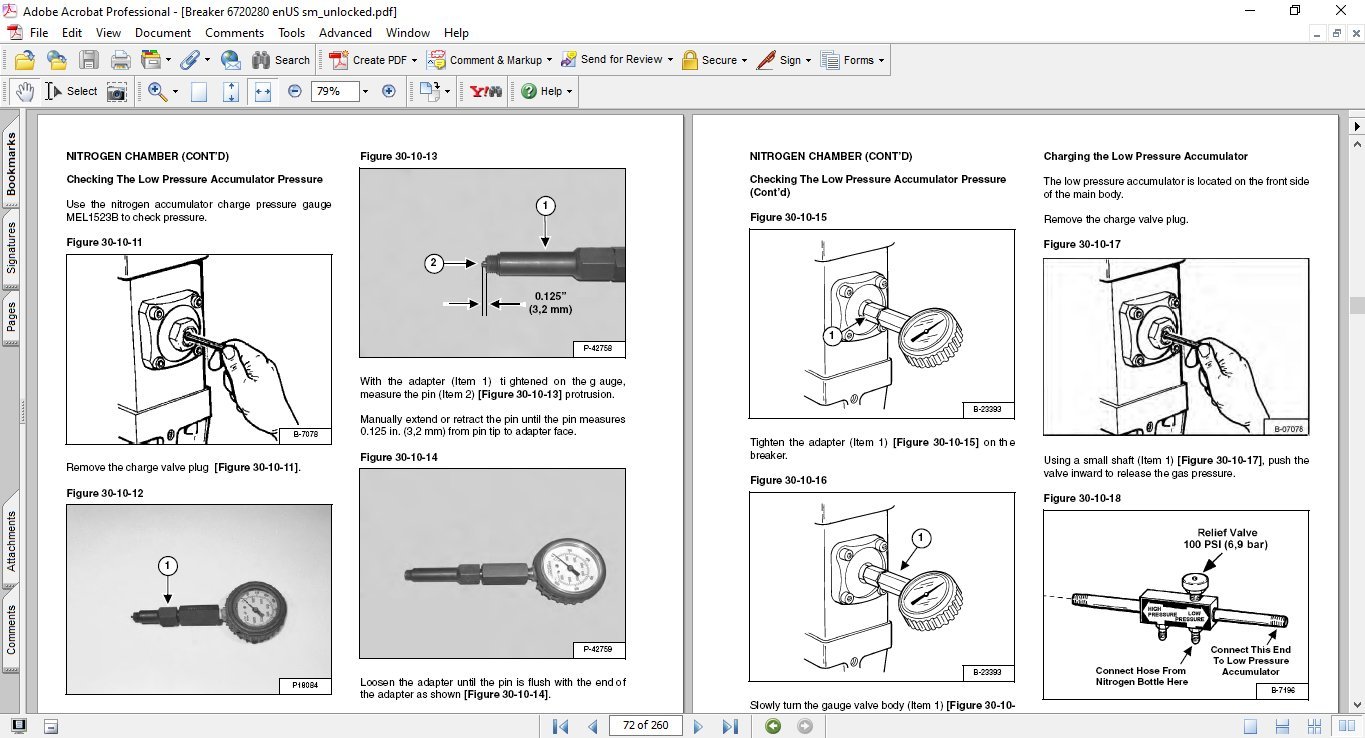

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS

TROUBLESHOOTING THE HYDRAULIC BREAKER

2500/3500 HYDRAULIC BREAKER SERVICE

CHECKING MOUNTING BOLT TORQUE

DISASSEMBLY AND ASSEMBLY

HYDRAULIC BREAKER LUBRICATION

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS (2500)

SPECIFICATIONS (3500)

TROUBLESHOOTING THE HYDRAULIC BREAKER

2560/3560 HYDRAULIC BREAKER SERVICE

DISASSEMBLY AND ASSEMBLY

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS

TROUBLESHOOTING THE HYDRAULIC BREAKER

2570/3570 HYDRAULIC BREAKER SERVICE

CHECKING MOUNTING BOLT TORQUE

DISASSEMBLY AND ASSEMBLY

HYDRAULIC BREAKER LUBRICATION

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS

TROUBLESHOOTING THE HYDRAULIC BREAKER

5060 HYDRAULIC BREAKER SERVICE

BOB-TACH INSPECTION

DAILY INSPECTION

DISASSEMBLY AND ASSEMBLY

HYDRAULIC BREAKER LUBRICATION

HYDRAULIC BREAKER MOUNT INSPECTION

LOADER MOUNT REMOVAL AND INSTALLATION

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS

TOOL BIT REMOVAL AND INSTALLATION

TROUBLESHOOTING

5500 HYDRAULIC BREAKER SERVICE

CHECKING MOUNTING BOLT TORQUE

HYDRAULIC BREAKER LUBRICATION

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS

TROUBLESHOOTING THE HYDRAULIC BREAKER

6560 HYDRAULIC BREAKER SERVICE

CHECKING MOUNTING BOLT TORQUE

HYDRAULIC BREAKER LUBRICATION

NITROGEN CHAMBER

PARTS IDENTIFICATION

SPECIFICATIONS

TROUBLESHOOTING THE HYDRAULIC BREAKER

Understanding the Bobcat Hydraulic Breaker

The Bobcat hydraulic breaker is a powerful attachment designed to enhance the functionality of Bobcat skid-steer loaders and other compatible machinery. This tool is primarily utilized for demolition and heavy-duty tasks, where breaking through concrete, asphalt, and other hard materials is required. The hydraulic breaker operates using the hydraulic system of the Bobcat machine, efficiently converting hydraulic energy into mechanical force to deliver impactful blows on surfaces.

Key components of a Bobcat hydraulic breaker include the cylinder, tool, and housing. The cylinder houses the piston that, when energized by hydraulic fluid, moves to strike the tool. The tool is the hardened steel point that contacts the surface, while the housing protects the inner workings from debris and damage. This design allows for the reliable performance expected from a hydraulic attachment, making it a favored choice among construction and demolition professionals.

Bobcat hydraulic breakers come in various models and specifications, each tailored for different applications and machine compatibilities. For instance, some models are lightweight for smaller jobs, while others are built for more intensive operations. Users can opt for models rated for specific flows and pressures to match their Bobcat machines’ capabilities. However, the advantages of using a hydraulic breaker often stem from its efficiency, which allows operators to complete tasks faster than traditional methods, while minimizing wear on the host machine.

It is crucial for operators to prioritize regular maintenance to prevent common issues, such as reduced power output or excessive wear on the tool. Proper care and timely servicing can significantly extend the lifespan of the hydraulic breaker, ensuring optimal performance and reliability on the job site. Overall, the Bobcat hydraulic breaker is an indispensable tool for professionals dealing with demolition and heavy construction projects, exemplifying efficiency and power in handling tough materials.

Service and Repair: Step-by-Step Instructions

Performing regular service and repair on Bobcat hydraulic breakers is essential for maintaining their functionality and extending their lifespan. The following step-by-step guide outlines the necessary procedures, tools, and safety precautions required for effective maintenance.

Before starting any service, gather the necessary tools including wrenches, screwdrivers, pliers, a hammer, and a torque wrench. It is also advisable to have hydraulic fluid and seals to replace as needed. Upon gathering tools, ensure you prioritize safety. Always wear appropriate personal protective equipment (PPE) such as gloves and safety goggles, and ensure that the work area is clean and free from hazards.

To begin, refer to the Bobcat hydraulic breaker service manual for specific details related to your model. Always adhere to the manufacturer’s specifications for both servicing and repairs. Start with a visual inspection of the hydraulic breaker. Check for signs of wear, leaks, and any physical damage. If any irregularities are noted, document them before proceeding to the troubleshooting phase.

Common issues with hydraulic breakers include inadequate impact energy, slow operation, and leaks. For each of these problems, troubleshoot methodically. For instance, if impact energy is lacking, verify that the hydraulic fluid is at the appropriate level and that there are no obstructions in the hydraulic system. Inspect the seals for any signs of wear and replace them as needed to prevent leaks.

Once any issues are identified, follow the repair procedures outlined in the service manual. This may include disassembling parts to replace seals and components or tightening connections to prevent hydraulic fluid loss. After completing repairs, reassemble the unit carefully, ensuring all parts are fitted securely and aligned correctly. Finally, test the hydraulic breaker to confirm proper operation and performance.