Package Include

Bobcat Tree Vibrator Single and Double Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-108

Publication Number

6901163 (December 2001)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 35 mb

With This Original Factory Service Repair Manual The Technician can Find and Solve any problems encountered in the operation of your Bobcat Vibrator Models of :

Model 30 [S.N 991600101 & Above]

Model 40 [S.N 991700101 & Above]

This is Original factory pdf manual and This pdf Service Repair Manual very clear and it is 100% printable version, contains with high quality images and diagrams,

This is True Electronic pdf copy, not scanned version

If you are looking for a specific manual and if you can not find it on our store, contact our customer support team, with details of the required manual, we will do our absolute best to acquire it for you.

Understanding Bobcat Tree Vibrators: Functions and Features

Bobcat tree vibrators are specialized attachments designed to enhance efficiency in agricultural and landscaping applications, particularly for tree shaking. Their primary function is to effectively remove fruit from trees, significantly reducing harvesting time. These machines work by applying controlled vibrations to the tree trunk, dislodging ripe fruit while minimizing potential damage to the tree. This functionality is crucial in improving harvest quality and yield, making Bobcat tree vibrators an essential tool for professionals in the industry.

Bobcat offers both single and double service tree vibrators, each with distinct characteristics tailored to different operational needs. Single service vibrators are typically more lightweight and designed for smaller trees or orchards where fruit density is lower. In contrast, double service vibrators can handle larger trees and denser fruit clusters, leveraging their advanced hydraulic systems to apply more forceful vibrations. The choice between single and double service vibrators largely depends on the specific requirements of the job at hand, including the size of the trees and the desired harvest efficiency.

The key components of Bobcat tree vibrators include robust hydraulic systems, intuitive controls, and versatile attachments. The hydraulic system is critical, as it provides the necessary power for vibration while maintaining precise control over the intensity and duration of the shaking process. Operators will appreciate the ease of use offered by the control systems, which allow for quick adjustments based on the specific tree and fruit type. Additionally, various attachments can be utilized to further enhance functionality, ensuring compatibility with diverse tree species and conditions. When selecting a Bobcat tree vibrator, it is advisable to assess operational demands and consult with experts to make an informed decision that aligns with specific agricultural or landscaping goals.

Service and Repair Procedures for Bobcat Tree Vibrators

Proper service and repair procedures for Bobcat tree vibrators are essential to maintain optimal performance and ensure longevity of the equipment. Regular inspections are a crucial aspect of the maintenance schedule. Operators should conduct a comprehensive inspection every 50 hours of operation or at least once a month, whichever comes first. This evaluation includes checking for signs of wear and damage on components like hydraulic hoses, connectors, and drive mechanisms. Furthermore, it is advisable to maintain a log of these inspections to track performance trends over time.

Cleaning procedures also play a vital role in the maintenance of Bobcat tree vibrators. After each use, operators should remove dirt, debris, and other contaminants from the surface and crevices of the vibrators. A soft brush or compressed air can effectively eliminate dust and grime. Regular cleaning prevents accumulation, which can lead to potential malfunctions and reduced performance. In addition, ensure that the hydraulic system is free from contaminants by replacing the hydraulic fluid at recommended intervals as defined in the service manual.

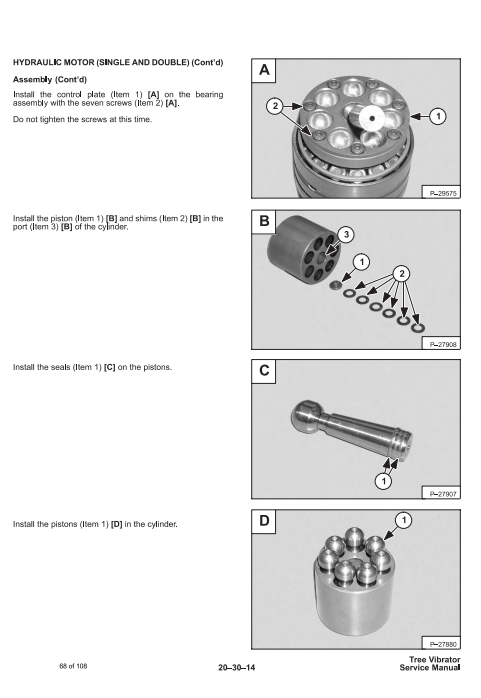

Common issues with single and double service vibrators include hydraulic fluid leaks, inconsistent vibration levels, and electrical malfunctions. When faced with these challenges, troubleshooting techniques are imperative. For hydraulic leaks, operators should inspect all connections and seals, tightening them as necessary. To address inconsistent vibration, check the component connections and motor functions. If electrical issues arise, consulting the wiring diagrams in the service manual can provide clarity. For more in-depth technical guidance, accessing the Bobcat repair manual is highly recommended. Sourcing genuine replacement parts is crucial for repairs; always use OEM parts to ensure compatibility and performance. Adhering to these service and repair procedures will contribute to keeping your Bobcat tree vibrators in peak condition, enhancing both safety and productivity.