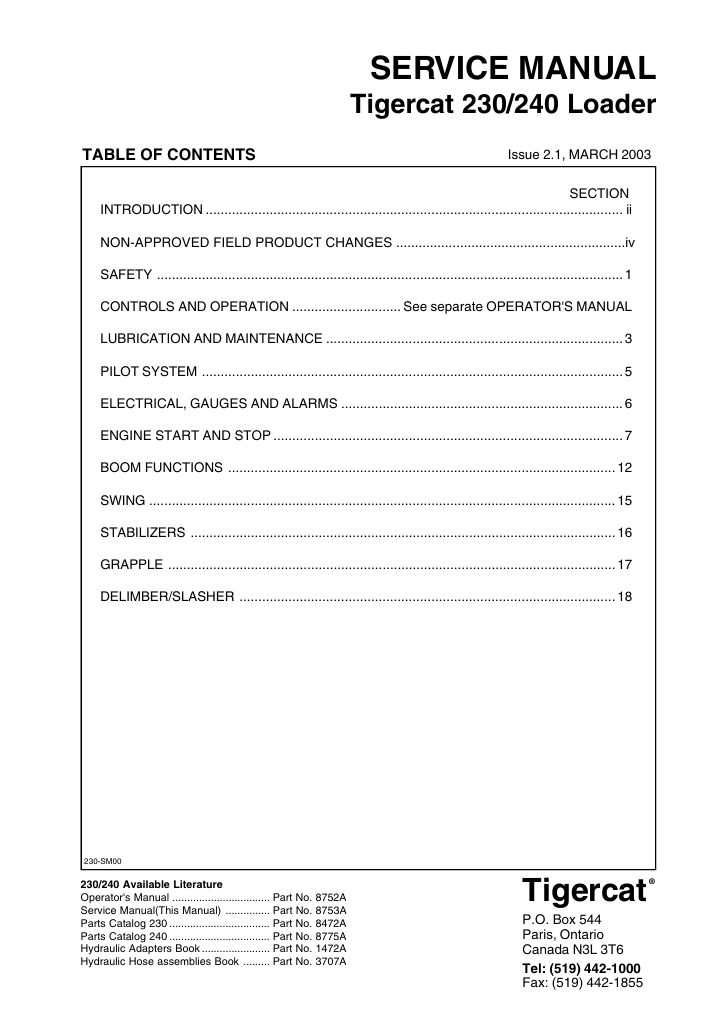

| Package include | Tigercat 230 Loader Service Repair Manual |

| Language | English |

| File Format | |

| Total Number of pages | 100 |

| Publication Number | Issue2.1,MARCH2003 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase. Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 4 MB |

| Compatible Machine Models | Tigercat 230 Loader |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Introduction to Tigercat 230 Loader Service Repair Manual

The Tigercat 230 Loader is an innovative and robust machine specifically designed for the demanding environments of forestry and construction. Known for its versatile capabilities, the Tigercat 230 is equipped with advanced hydraulic systems and a powerful engine, allowing it to excel in tasks such as material handling, log loading, and site preparation. Its uniquely engineered features, including a strong undercarriage and an operator-friendly cabin, provide not only enhanced performance but also improved comfort and productivity for operators during extended periods of usage. These attributes make the Tigercat 230 an invaluable asset for professionals in the industry.

Having a comprehensive service repair manual for the Tigercat 230 Loader is of paramount importance for any operation looking to maximize the machine’s performance and longevity. This manual serves as an essential resource, detailing maintenance schedules that help ensure the loader is always in optimal working condition. By adhering to proper maintenance protocols, operators can mitigate the risk of unexpected breakdowns and costly repairs that could otherwise disrupt operations. Furthermore, the Tigercat 230 Loader service repair manual includes thorough troubleshooting tips that empower operators to identify and resolve issues swiftly, reducing downtime.

In addition to maintenance and troubleshooting, the service manual provides detailed guides for servicing various components of the loader. From lubricating engine parts to adjusting hydraulic systems, these instructions are crucial for preserving the operational integrity of the equipment. The manual acts as a safeguard, ensuring that safety standards are upheld, and the performance of the loader is not compromised. By investing in and utilizing the Tigercat 230 Loader service repair manual, operators can enhance the machine’s efficiency, safety, and reliability over its service life.

Key Components and Maintenance Guidelines

The Tigercat 230 Loader integrates several critical components that contribute to its high performance and operational efficiency. Understanding these parts, including the engine, hydraulic system, and undercarriage, is paramount for proper maintenance and troubleshooting. The loader’s engine, generally a powerful diesel variant, is designed for durability and efficiency. Regular inspections of the engine are essential to identify any signs of wear, such as abnormal noises or reduced power output. Adhering to oil change intervals and monitoring fluid levels can dramatically enhance engine longevity.

The hydraulic system of the Tigercat 230 Loader plays a vital role in powering various functions, including lifting and maneuvering. Hydraulic fluid should be kept at optimal levels, and any leaks or fluctuations in performance must be addressed immediately. Failure to attend to hydraulic components can lead to operational failures that may impact productivity and safety. Regularly checking hydraulic hoses for signs of wear or damage will help in early detection of potential issues.

Another critical component is the undercarriage, which supports the overall stability and mobility of the loader. This includes tracks, rollers, and frames, all of which bear the load during operation. Lack of maintenance can lead to problems such as uneven wear or misalignment, resulting in increased costs for repair and replacement. Operators should be vigilant in conducting visual inspections and keeping vital areas free from debris and buildup.

For all components, the Tigercat 230 Service Repair Manual provides detailed steps for inspection, servicing, and troubleshooting. It is crucial to recognize the warning signs of wear, such as unusual sounds, vibrations, or malfunctions. Following a structured maintenance schedule not only improves the loader’s reliability but also significantly reduces downtime, ultimately enhancing its operational efficiency in any work environment.