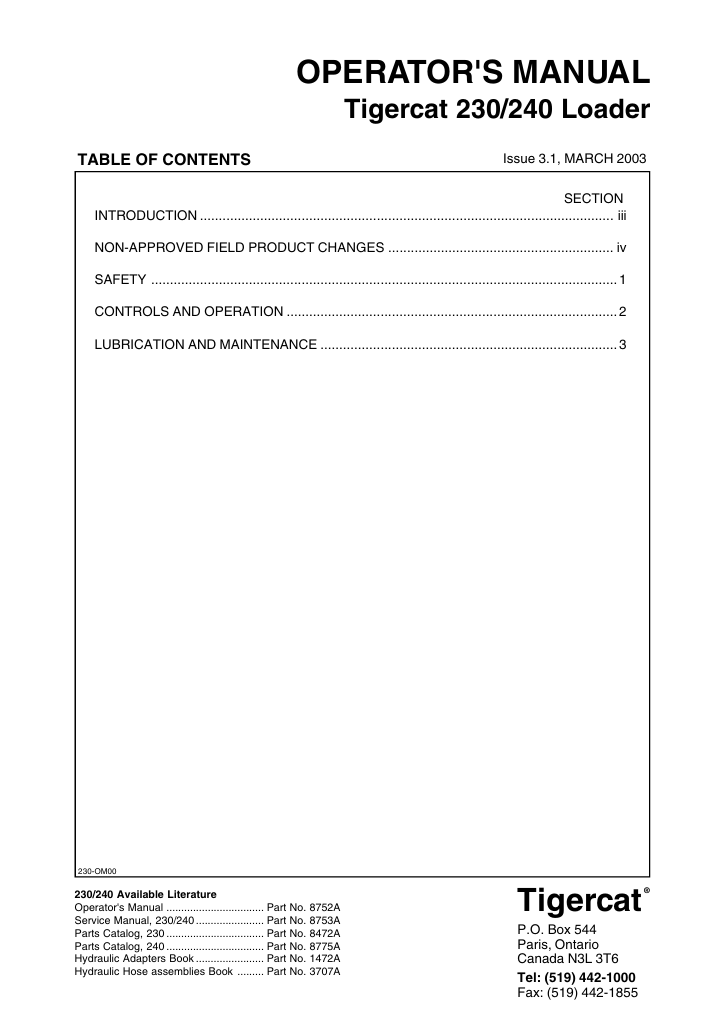

| Package include | Tigercat 230 Loader Operator’s Manual |

| Language | English |

| File Format | |

| Total Number of pages | 56 |

| Publication Number | Issue 3.1, MARCH 2003 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase. Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 4 MB |

| Compatible Machine Models | Tigercat 230 Loader |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Understanding the Tigercat 230 Loader: Overview and Specifications

The Tigercat 230 Loader is a cutting-edge machine designed for efficiency and robustness in challenging work environments. Engineered with advanced technology, the loader features a powerful Tier 4 final engine that delivers impressive performance, with outputs reaching up to 170 horsepower. This power enables the Tigercat 230 to handle demanding tasks such as material handling, earthmoving, and log handling with ease. The optimal load capacity of the loader is particularly noteworthy; it can handle loads of up to 3,500 pounds, making it well-suited for various construction and forestry applications.

One of the standout features of the Tigercat 230 Loader is its sophisticated hydraulic system. The machine is equipped with an efficient hydraulic circuit that ensures excellent responsiveness and control. This system not only enhances the operational capabilities but also significantly reduces cycle times. Operators will appreciate the superior lift and tilt functions that this hydraulic system provides, making it easier to engage with a variety of attachments suited to multiple tasks.

In terms of safety, the Tigercat 230 Loader is designed with the well-being of operators in mind. It includes features such as ROPS (Roll-Over Protective Structures) and FOPS (Falling Object Protective Structures) certification, ensuring maximum safety during operation. Its ergonomically designed operator cabin provides excellent visibility and comfort, facilitating efficient operation. Additionally, the machine is equipped with various monitoring systems that alert the operator to potential issues, allowing for proactive maintenance and reducing downtime.

For optimal performance, it is crucial to operate the Tigercat 230 Loader within its recommended operational conditions. These guidelines ensure that operators can maximize efficiency while maintaining safety, reducing the risk of accidents or equipment damage. Ultimately, understanding the specifications and capacity of the Tigercat 230 Loader is essential for operators striving to achieve top performance in their work environment.

Operating the Tigercat 230 Loader: Best Practices and Maintenance Tips

The Tigercat 230 Loader is a versatile machine designed to enhance productivity in various operational contexts. To ensure effective and safe use of this loader, it is essential to adhere to best practices from the operator’s manual. Starting the loader involves a thorough pre-operational check; this includes inspecting fluid levels such as oil and fuel, checking for any leaks, and confirming that safety features, like emergency brakes, are functioning properly. Following these steps sets a solid foundation for optimal performance.

When operating the Tigercat 230, the operator should engage the machine controls delicately and responsively. This includes using the joystick controls for smooth movement of the arms and attachments. Whether lifting, tilting, or using various attachments such as grapples or buckets, maintaining control and smooth operation is paramount. To maximize efficiency, operators should manipulate their attachments to avoid excess strain on the loader, thus preventing premature wear.

Routine maintenance is essential in extending the longevity of the Tigercat 230 Loader. Daily inspections are crucial; operators should check tire pressure, inspect hydraulic hoses for any signs of wear, and ensure that all safety equipment is in proper working order. It is also important to adhere to a scheduled maintenance plan as outlined in the operator’s manual, which includes oil changes, filter replacements, and other essential servicing tasks.

In addition to following the operator’s manual, troubleshooting common issues such as unusual noises, difficulty in maneuvering, or warning lights can save time and resources. Addressing these problems promptly can prevent escalation and downtime. By implementing these best practices and maintenance tips, operators can ensure that the Tigercat 230 Loader performs optimally and remains a reliable asset on site.