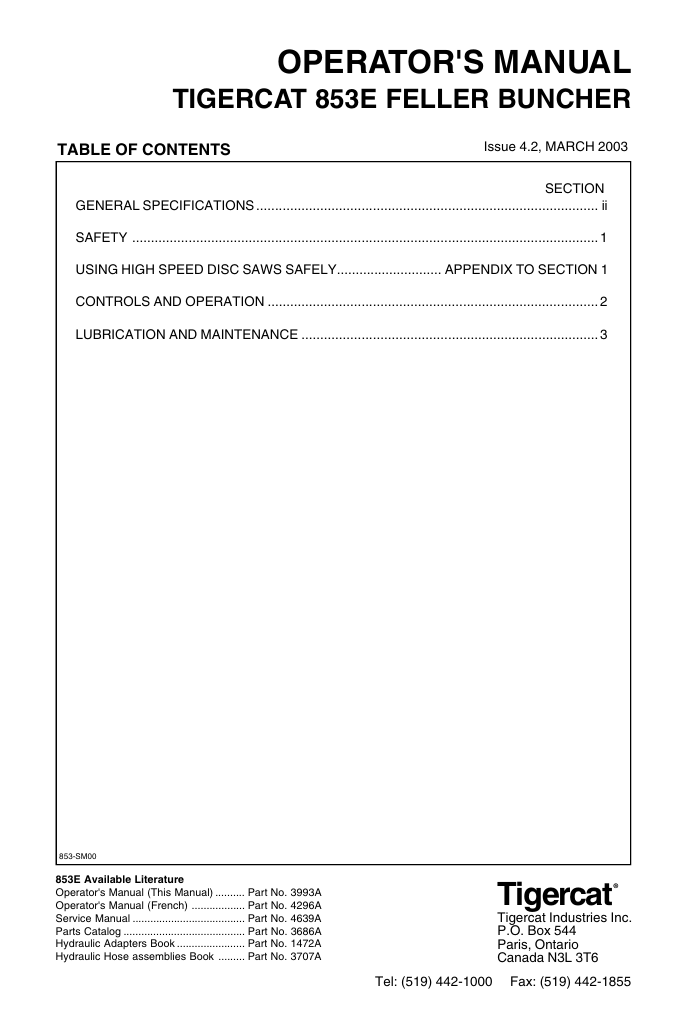

| Package include | Tigercat 853E Feller Buncher Operator’s Manual |

| Language | English |

| File Format | |

| Total Number of pages | 64 |

| Publication Number | Issue4.2,MARCH2003 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase.Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 4 MB |

| Compatible Machine Models | Tigercat 853E Feller Buncher |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Overview of the Tigercat 853E Feller Buncher

The Tigercat 853E Feller Buncher represents a significant advancement in forestry equipment, specifically designed to enhance logging operations. This robust machine boasts a powerful engine, specifically integrating a Tier 4 final engine, which assures compliance with environmental regulations while delivering exceptional performance. With a rated horsepower of approximately 200, the 853E executes heavy-duty tasks with remarkable efficiency, effectively minimizing downtime during operations.

One of the standout features of the Tigercat 853E is its advanced hydraulics system. This system enables swift and precise movements of the felling head, allowing operators to navigate various terrains with ease. The quick-attach feature further enhances operational efficiency, enabling easy and rapid changes to different attachments depending on the specific requirements of a job. As a result, the 853E adapts seamlessly to diverse forestry applications, whether it be thinning stands or clear-cut harvesting.

Operator comfort is paramount in the design of the 853E. The cabin is spacious and ergonomically crafted, offering excellent visibility and reducing fatigue during prolonged use. High-quality seating and superior climate control features ensure that operators remain comfortable regardless of external weather conditions. Moreover, safety is prioritized with advanced technologies such as a reinforced cabin structure and comprehensive monitoring systems that alert operators to any potential issues.

In addition to its core functionalities, the Tigercat 853E Feller Buncher emphasizes user-friendliness. The intuitive control system simplifies operation, allowing even novice operators to navigate the machine effectively. This combination of power, comfort, and versatility establishes the 853E as a preferred choice within the industry, catering to the demands of modern logging operations.

Operating Procedures and Maintenance Guidelines

Operating the Tigercat 853E feller buncher requires adherence to meticulous procedures to ensure safety and efficiency. Operators must first conduct a thorough pre-operation inspection, examining critical components such as the hydraulic system, cutting head, and undercarriage. Following the guidelines in the operator’s manual can prevent costly damages and performance issues. It is essential to ensure that all safety devices are functioning correctly before starting the machine.

When initializing the Tigercat 853E, operators should ensure that the machine is on a stable surface. Engage the parking brake and verify that all implement controls are in a neutral position. Starting the engine should be done according to the outlined steps, beginning with turning the key to the ‘on’ position and waiting for the system checks to complete before engaging the starter. Following these initial steps will help promote operational safety and efficiency during use.

During operation, operators should maintain constant awareness of their surroundings to ensure safety. Operators must familiarize themselves with various controls and maintain a steady hand on the joysticks for optimal maneuverability. Following the recommended operational speeds and being aware of potential obstacles are essential strategies for maximizing efficiency during logging tasks. Regular communication with ground personnel enhances safety and operational success.

Once the task is complete, proper shutdown procedures must be followed. This includes lowering the cutting head, positioning the machine safely away from active workloads, and disengaging hydraulic systems before shutting down the engine. Adherence to these practices can significantly reduce wear and tear on components.

Maintenance is pivotal for the Tigercat 853E’s longevity. Operators should implement a routine maintenance schedule outlined in the operator’s manual, which includes regular inspections, fluid level checks, and parts servicing. Being vigilant about minor issues can prevent major breakdowns, ensuring that the feller buncher remains efficient and operational throughout its service life. In the case of any irregularities, operators should refer to the troubleshooting section to address common concerns promptly.