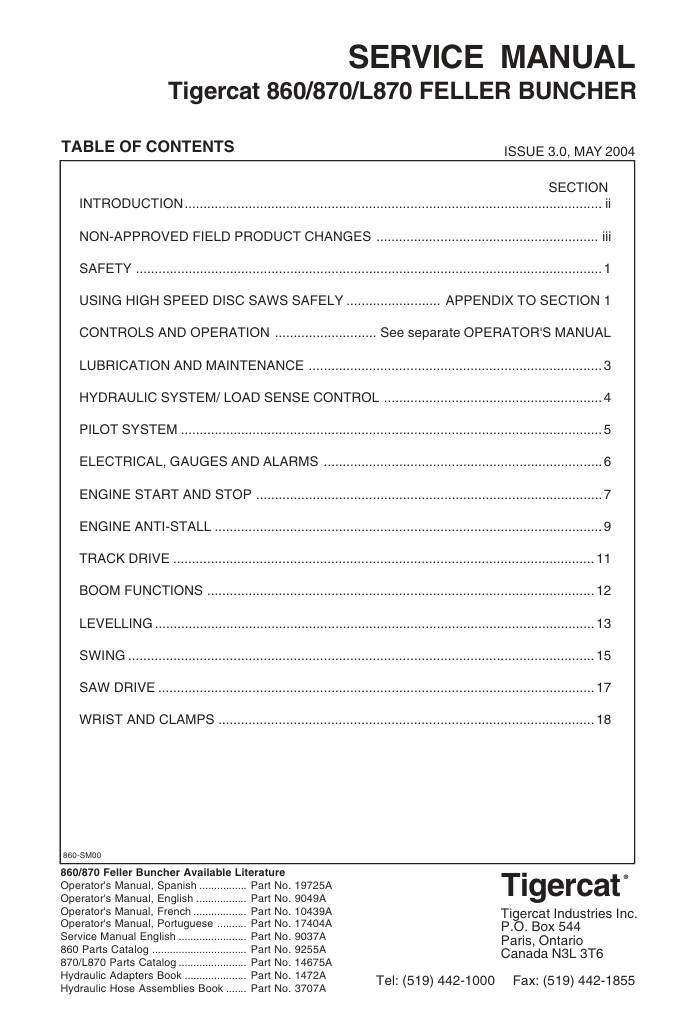

| Package include | Tigercat 870 Feller Buncher Service Repair Manual |

| Language | English |

| File Format | |

| Total Number of pages | 252 |

| Publication Number | ISSUE 3.0, MAY 2004 |

| Compatible | Windows system / Mac system / Android / IOS / Chrome OS / Any device capable of opening a PDF file |

| Additional Requirement | User must have any software that can open the pdf format |

| Shipping Policy | All of our products are digital and hence supplied immediately upon purchase. Once your purchase is complete, you will have immediate access to the product via a download link |

| Download Size | Total download size: 18 MB |

| Compatible Machine Models | Tigercat 870 Feller Buncher |

| Sample Preview Yes | Before purchasing the entire pdf handbook, please get sample preview of this pdf manual and ensure it is suitable with your model |

| Sample Preview Link | DOWNLOAD SAMPLE PREVIEW |

Overview of the Tigercat 870 Feller Buncher

The Tigercat 870 Feller Buncher represents a significant advancement in forestry machinery, designed to meet the demanding demands of modern timber harvesting. This powerful machine is engineered to efficiently fell, cut, and bundle trees, making it an essential tool for forestry applications. The unique design of the Tigercat 870 incorporates a robust frame and high-performance hydraulic systems that work together to enhance its performance in even the most challenging terrains.

One of the standout features of the Tigercat 870 is its exceptional maneuverability, ensuring that operators can navigate through dense forests with ease. It is equipped with a specialized harvesting head that not only cuts trees with precision but also allows for quick processing, helping to maximize productivity. This capability is particularly valuable in environments where time and efficiency are critical, significantly reducing the operational time required to complete a logging project.

In addition to its mechanical advantages, the Tigercat 870 Feller Buncher is designed with operator comfort and safety in mind. The spacious cabin is thoughtfully engineered to provide excellent visibility and ergonomics, which aids in minimizing operator fatigue during long hours of work. Furthermore, the machine is outfitted with advanced technology that monitors performance metrics, allowing users to optimize operations and reduce costs effectively.

As a result of its innovative design and operational capabilities, the Tigercat 870 serves as a vital asset in the forestry sector. It facilitates enhanced productivity and contributes to lower operational costs, thus providing long-term benefits to users. Understanding the key features and practical advantages of this machine is crucial for achieving optimal performance and maintenance, setting the stage for more in-depth discussions on its service and repair manual.

Essential Maintenance and Repair Procedures

The Tigercat 870 Feller Buncher, widely recognized for its efficiency and durability, requires routine maintenance and careful repair to sustain its exemplary performance in forest operations. Central to the longevity of this machine is the adherence to the essential maintenance protocols delineated in the service repair manual. Initially, operators should implement regular maintenance checks that focus on various components, including the hydraulic system and engine, which are critical for optimal operation.

Hydraulic system maintenance is paramount as this system supports the machine’s functions and movements. Operators should routinely inspect hydraulic fluid levels, check for leaks, and monitor the condition of hoses and connections. Maintaining the correct hydraulic fluid type, as specified in the service manual, directly correlates with performance efficiency and reduces the risk of machinery failure. Moreover, replacing hydraulic filters at prescribed intervals ensures the system remains free from contaminants, thereby prolonging its life and enhancing functionality.

Engine care is another vital aspect of maintaining the Tigercat 870. Regular oil and filter changes are imperative for engine health, ideally performed according to the operational hours stated in the manual. Additionally, it is crucial to monitor coolant levels and check the condition of the air intake system to prevent overheating and ensure clean airflow.

Lastly, using genuine Tigercat parts for repairs cannot be overlooked, as these components are specifically designed to fit and function with the machine, validating performance and safety standards. By focusing on these maintenance and repair procedures outlined in the service manual, operators can effectively manage their Feller Bunchers, ensuring robust operation and extended lifespan in operational settings.